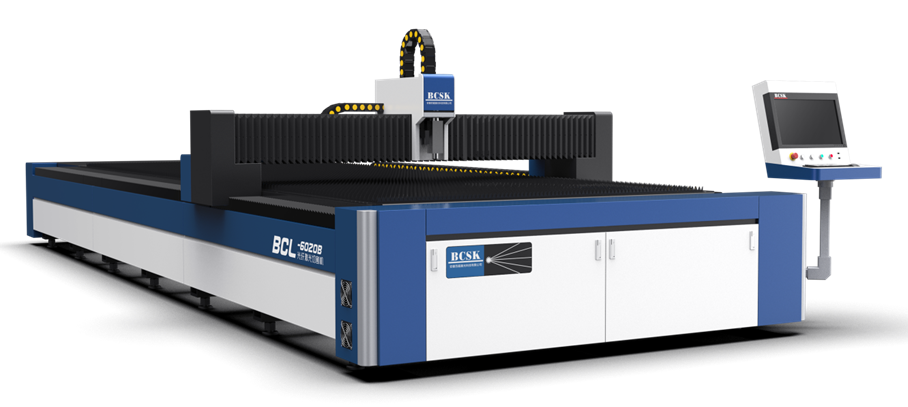

laser pipe cutting machine price

The laser pipe cutting machine price reflects a significant investment in advanced manufacturing technology, offering exceptional value through its precision cutting capabilities and versatility. These machines typically range from $50,000 to $300,000, depending on specifications, power output, and additional features. The pricing structure considers the machine's ability to handle various pipe diameters, typically from 20mm to 230mm, and its capacity to cut different materials including carbon steel, stainless steel, and aluminum. Modern laser pipe cutting machines incorporate advanced CNC systems, automated loading mechanisms, and sophisticated software interfaces that streamline the production process. The price point also accounts for essential features such as automatic focus control, real-time monitoring systems, and intelligent nesting capabilities that minimize material waste. These machines deliver consistent cutting quality with minimal heat affected zones, achieving cutting speeds of up to 40m/min depending on material thickness. The investment typically includes comprehensive warranty coverage, installation services, operator training, and technical support, ensuring maximum return on investment through improved productivity and reduced operational costs.