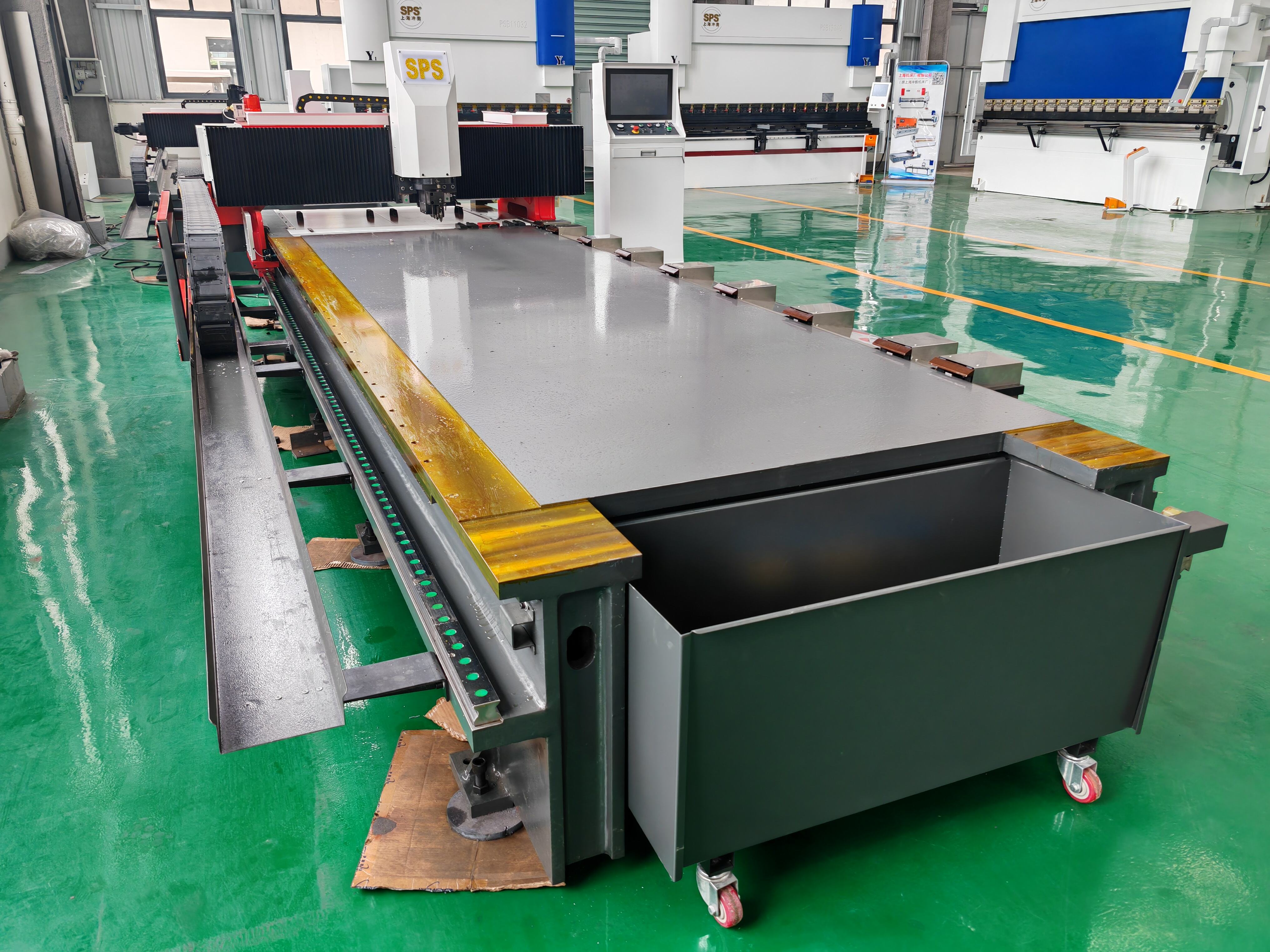

mini press brake

The mini press brake represents a compact yet powerful solution for precision metal bending operations. This versatile machine integrates advanced technological features into a space-efficient design, making it ideal for small to medium-sized workshops and fabrication facilities. Operating through a combination of mechanical and hydraulic systems, the mini press brake delivers consistent bending accuracy while maintaining a significantly smaller footprint compared to traditional press brakes. It excels in forming various metal materials, including sheet metal, aluminum, and mild steel, with typical thickness capacities ranging from 0.5mm to 6mm. The machine's control system offers both manual and CNC programming options, enabling operators to achieve complex bending sequences with remarkable precision. Notable features include adjustable back gauge systems, user-friendly interfaces, and quick-change tooling capabilities that minimize setup time. The mini press brake's compact design doesn't compromise its fundamental capabilities, offering bending forces typically ranging from 20 to 40 tons, sufficient for most small-scale manufacturing requirements. Safety features such as light curtains, emergency stop functions, and finger protection systems ensure operator security while maintaining productivity. The machine's versatility extends to its ability to perform various bending operations, including V-bending, U-bending, and hemming, making it an invaluable tool for custom fabrication work.