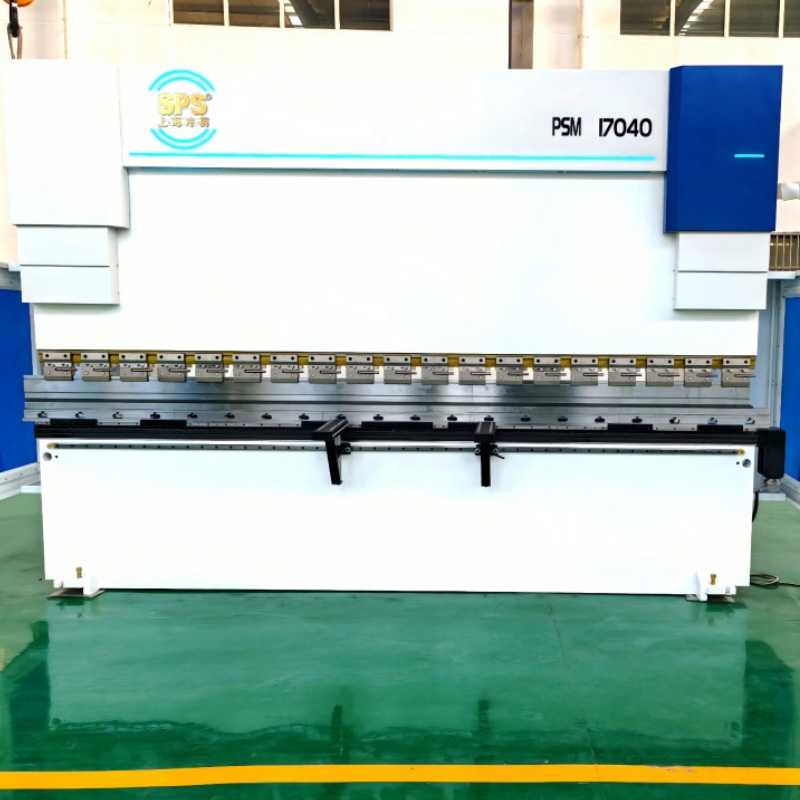

manual press brake

A manual press brake is a fundamental metalworking tool designed for precision bending and forming of sheet metal. This versatile machine employs a simple yet effective mechanical system consisting of a bottom die and an upper punch that work together to create accurate bends. Operating through a manually controlled mechanism, typically utilizing a flywheel or lever system, it allows operators to apply precise pressure and control over the bending process. The machine's bed length and tonnage capacity determine the size and thickness of materials it can handle. Manual press brakes feature adjustable backstops for consistent bend depths and various die sets to accommodate different bend angles and profiles. These machines excel in small to medium-scale operations, particularly in workshops and maintenance facilities where versatility and cost-effectiveness are prioritized. Their straightforward mechanical design ensures reliability and minimal maintenance requirements while providing consistent results in metal forming operations. The machine's ability to perform multiple bending operations, including V-bends, U-bends, and channel bends, makes it an invaluable tool for fabricating brackets, panels, and custom metal components.