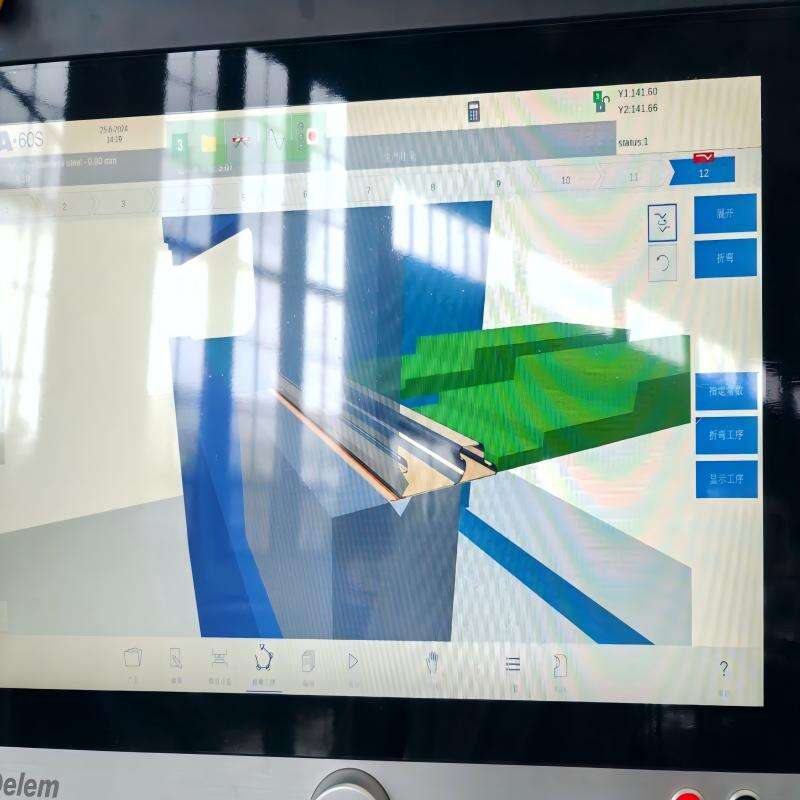

metal press brake

A metal press brake is a sophisticated piece of manufacturing equipment designed to bend and form sheet metal with precision and consistency. This versatile machine utilizes a hydraulic, mechanical, or electric-powered ram that presses metal between a punch and die to create precise bends and forms. Modern press brakes feature advanced CNC controls, allowing for programmable bend sequences and automated operations. They come in various sizes and capacities, typically ranging from small benchtop units to large industrial machines capable of handling sheets several meters in length. The machine's bending force is measured in tons, with capabilities ranging from 20 to over 1000 tons depending on the model. Press brakes employ various tooling options, including V-dies, gooseneck punches, and hemming tools, enabling them to create complex profiles and shapes. The technology incorporates advanced safety features such as light curtains, physical guards, and emergency stop systems to protect operators. These machines are essential in industries such as automotive manufacturing, aerospace, construction, and general fabrication, where precise metal forming is crucial for producing components ranging from simple brackets to complex architectural elements.