plasma laser cutting machine

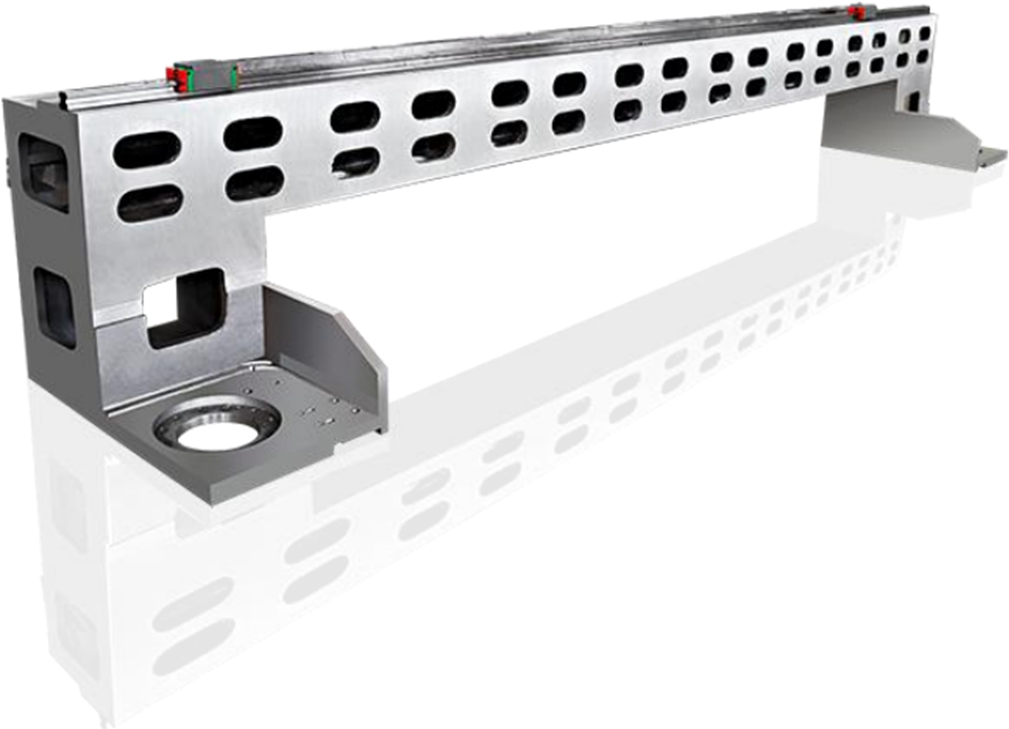

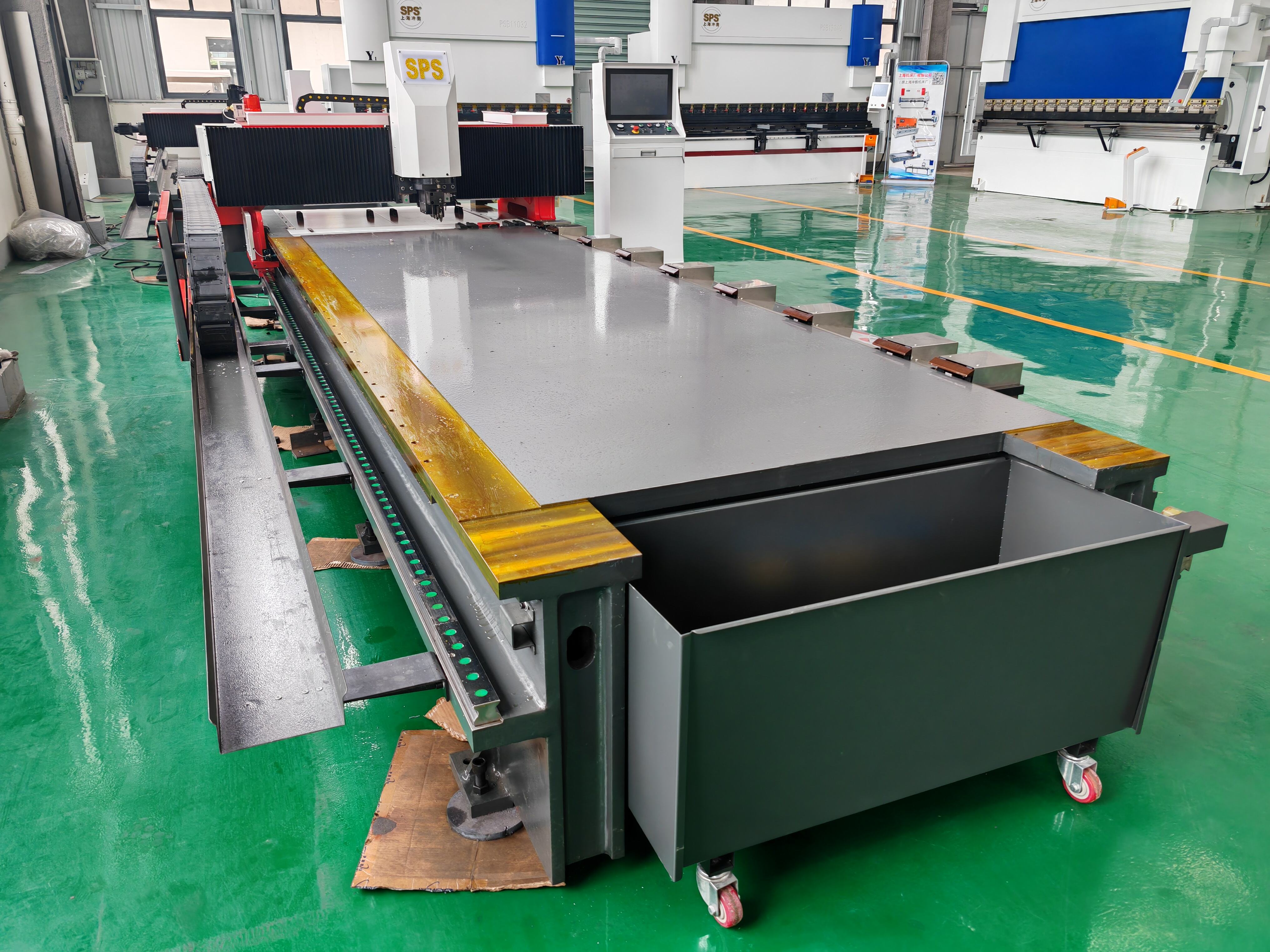

The plasma laser cutting machine represents a cutting-edge advancement in industrial manufacturing technology, combining the precision of laser systems with the power of plasma cutting. This sophisticated piece of equipment utilizes a high-temperature plasma arc to cut through electrically conductive materials with exceptional accuracy and speed. The machine's core functionality revolves around its ability to generate plasma by ionizing gas with electrical energy, creating temperatures that can exceed 20,000°C. This intense heat effectively melts and removes material along the cutting path, resulting in clean, precise cuts. The system incorporates advanced CNC control systems that ensure precise movement and cutting patterns, allowing for complex designs and intricate details. The machine's technological features include automatic height control, which maintains optimal distance between the torch and workpiece, multi-axis positioning capabilities for diverse cutting angles, and intelligent nesting software that maximizes material usage. It excels in processing various materials, including steel, aluminum, copper, and other conductive metals, with thickness capabilities ranging from thin sheets to heavy plates. The integration of modern sensing technologies and real-time monitoring systems ensures consistent cut quality and operational safety. This versatile tool finds extensive applications across industries, from automotive manufacturing and heavy equipment fabrication to architectural metalwork and precision parts production.