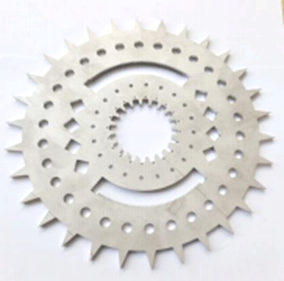

jewelry laser cutting machine

The jewelry laser cutting machine represents a pinnacle of precision engineering in the jewelry manufacturing industry. This sophisticated equipment utilizes advanced laser technology to perform intricate cutting, engraving, and marking operations on various precious metals and materials. Operating with wavelengths specifically optimized for jewelry applications, these machines can achieve microscopic precision down to 0.01mm, enabling the creation of complex patterns and designs that would be impossible with traditional methods. The machine features a high-powered laser source, typically ranging from 20W to 50W, coupled with a precision-controlled motion system that ensures accurate material processing. Its computer numerical control (CNC) system allows for seamless integration with popular CAD/CAM software, enabling direct translation of digital designs into physical pieces. The machine's versatility extends to processing various materials including gold, silver, platinum, titanium, and even precious stones. Advanced safety features include enclosed working chambers with viewing windows, fume extraction systems, and emergency stop mechanisms. The system's user-friendly interface allows operators to adjust parameters such as cutting speed, power output, and focal length, ensuring optimal results for different materials and designs.