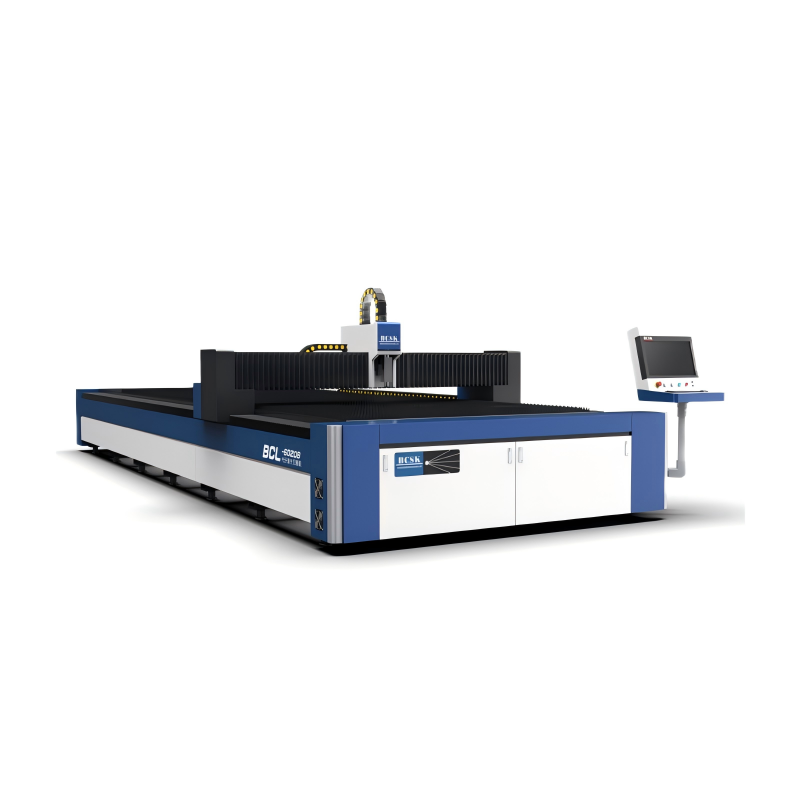

steel laser cutting machine

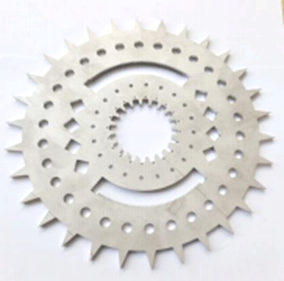

Steel laser cutting machines represent a pinnacle of modern manufacturing technology, offering precision cutting capabilities for various metal applications. These advanced systems utilize high-powered laser beams to efficiently cut through steel materials with exceptional accuracy and speed. The machine's cutting mechanism operates through a focused laser beam that melts, burns, or vaporizes the material, while a high-pressure gas removes the molten metal from the cut edge. This technology enables the creation of intricate designs and patterns with minimal material waste and superior edge quality. The cutting process is entirely computer-controlled through CNC (Computer Numerical Control) systems, allowing for precise reproduction of complex shapes and patterns. Modern steel laser cutting machines come equipped with advanced features such as automatic material handling systems, real-time process monitoring, and intelligent nesting software that optimizes material usage. These machines can handle various steel thicknesses, from thin sheets to thick plates, and can process different types of steel, including mild steel, stainless steel, and high-strength steel variants. The versatility of these machines makes them indispensable in industries such as automotive manufacturing, aerospace, construction, and general fabrication works.