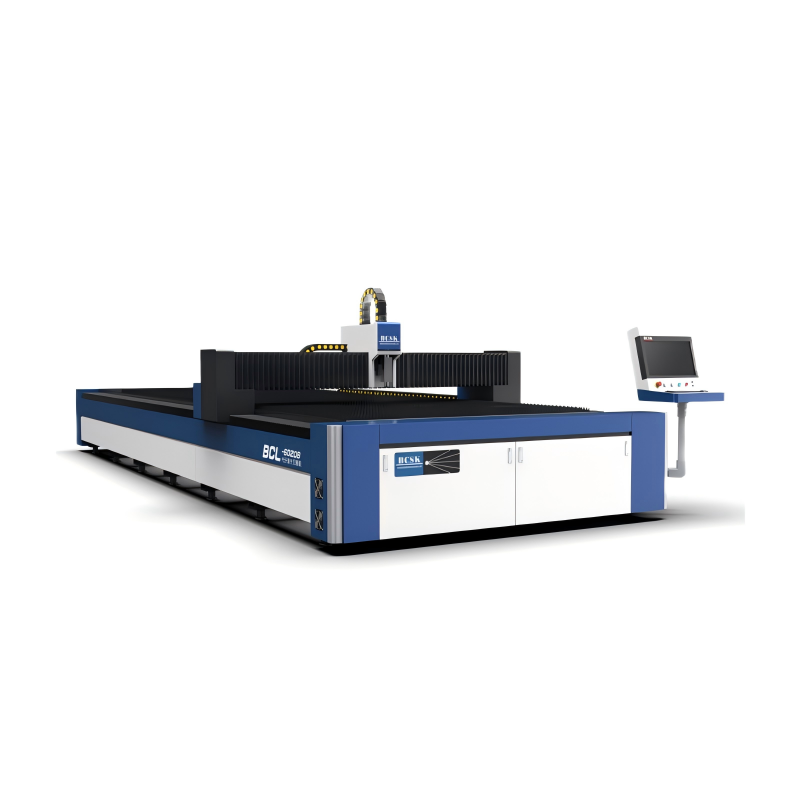

used laser cutting machine

Used laser cutting machines represent a cost-effective solution for manufacturing operations, combining precision engineering with proven reliability. These machines utilize advanced laser technology to deliver accurate cuts across various materials, including metals, plastics, and composites. The robust construction and sophisticated control systems ensure consistent performance, while the integrated cooling systems maintain optimal operating temperatures for extended production runs. Modern used laser cutting machines typically feature CNC capabilities, allowing for programmable cutting patterns and automated operation sequences. The machines often include automatic material handling systems, reducing manual intervention and improving workflow efficiency. With cutting speeds ranging from 20 to 100 meters per minute depending on material thickness, these systems maintain high productivity levels while achieving cutting accuracies within 0.1mm. Many units come equipped with multiple cutting heads, enabling simultaneous operations and increased output. The integration of advanced sensing technologies helps maintain cut quality by automatically adjusting laser power and focus based on material variations. These machines also incorporate safety features such as enclosed cutting areas and emergency shutdown systems, ensuring operator protection while maintaining productive operation.