laser cutting welding machine

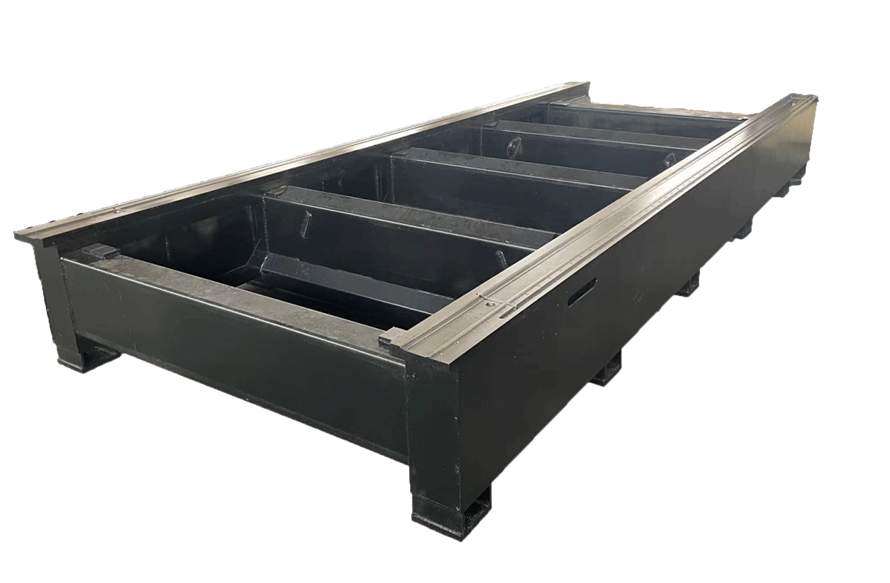

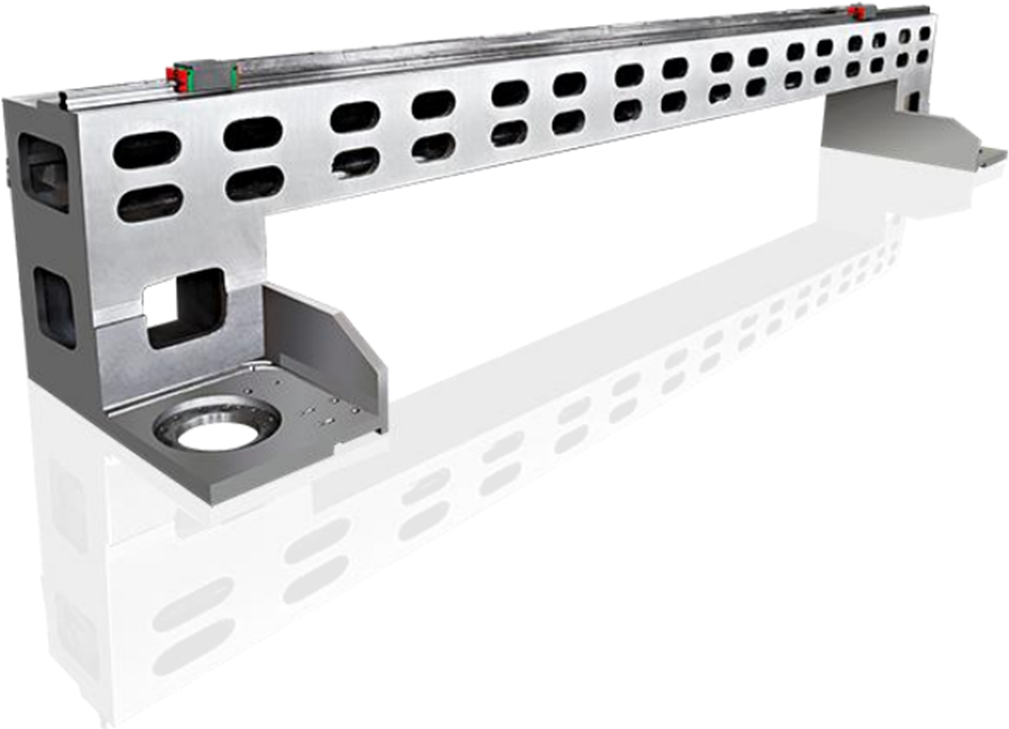

The laser cutting welding machine represents a pinnacle of modern manufacturing technology, combining precision cutting and welding capabilities in a single versatile unit. This advanced system utilizes high-powered laser beams to perform both cutting and welding operations with exceptional accuracy and speed. The machine's sophisticated control system enables seamless transitions between cutting and welding functions, allowing for efficient processing of various materials including steel, aluminum, copper, and other metals. The integrated design features advanced beam focusing technology that ensures precise energy distribution, resulting in clean cuts and strong welds. With computerized numerical control (CNC) capabilities, the machine can execute complex patterns and joints with minimal human intervention. The system's dual functionality eliminates the need for separate cutting and welding equipment, optimizing floor space and reducing capital investment. The machine incorporates real-time monitoring systems that maintain consistent quality throughout the operation, while automatic parameter adjustment ensures optimal performance across different material types and thicknesses. Safety features include enclosed processing areas and advanced fume extraction systems, protecting operators while maintaining a clean working environment. The versatility of the laser cutting welding machine makes it particularly valuable in industries such as automotive manufacturing, aerospace, metal fabrication, and precision engineering.