mini waterjet cutting machine

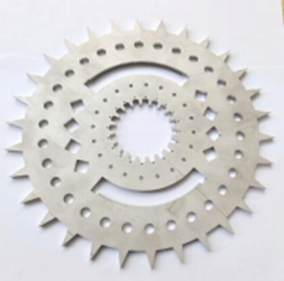

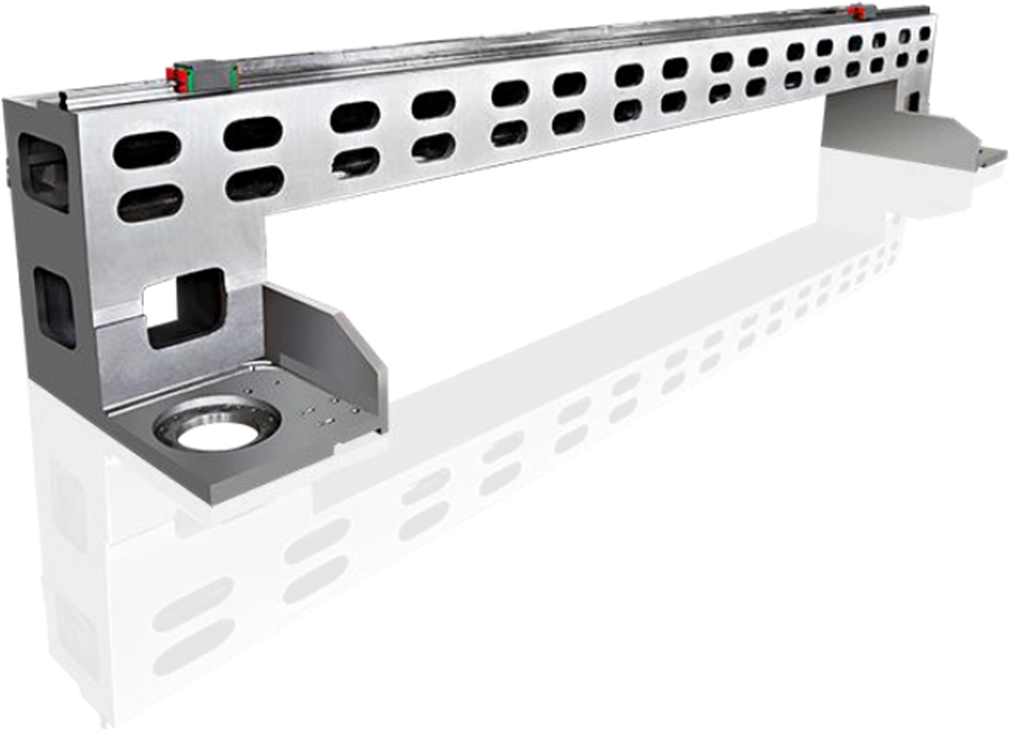

The mini waterjet cutting machine represents a breakthrough in precision cutting technology, offering industrial-grade capabilities in a compact form factor. This innovative device utilizes high-pressure water mixed with abrasive particles to create precise cuts across various materials, including metals, stone, glass, and composites. Operating at pressures up to 60,000 PSI, the machine delivers exceptional cutting accuracy while maintaining material integrity. The system features an advanced CNC control interface that enables users to execute complex cutting patterns with minimal setup time. Its compact design, typically measuring less than 4 square meters in footprint, makes it ideal for small workshops and specialized manufacturing facilities. The machine incorporates smart nesting software that optimizes material usage and reduces waste, while its precision movement system achieves positioning accuracy within 0.1mm. The integrated water recycling system minimizes resource consumption, making it both environmentally friendly and cost-effective. Modern mini waterjet cutting machines also include remote monitoring capabilities, allowing operators to track cutting progress and system performance through mobile devices or computers.