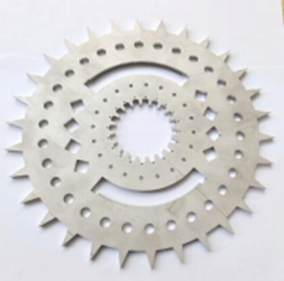

industrial water jet cutter

The industrial water jet cutter represents a cutting-edge manufacturing technology that harnesses the power of highly pressurized water mixed with abrasive particles to cut through various materials with exceptional precision. Operating at pressures up to 90,000 PSI, these sophisticated machines direct a focused stream of water and abrasive material through a specialized nozzle, enabling precise cutting of materials ranging from metal and stone to glass and composites. The system consists of several key components, including a high-pressure pump, an abrasive delivery system, a cutting head, and a computer-controlled motion system. Modern water jet cutters incorporate advanced CNC technology, allowing for automated operation and complex cutting patterns. The cutting process is cold, eliminating heat-affected zones and material distortion common in thermal cutting methods. This technology offers unmatched versatility in material processing, capable of achieving intricate designs with tolerances as tight as ±0.005 inches. The water jet cutting process is environmentally friendly, using primarily water and natural abrasive materials, making it a sustainable choice for manufacturing operations. These machines excel in both prototype development and high-volume production scenarios, offering scalability and consistency in cutting performance.