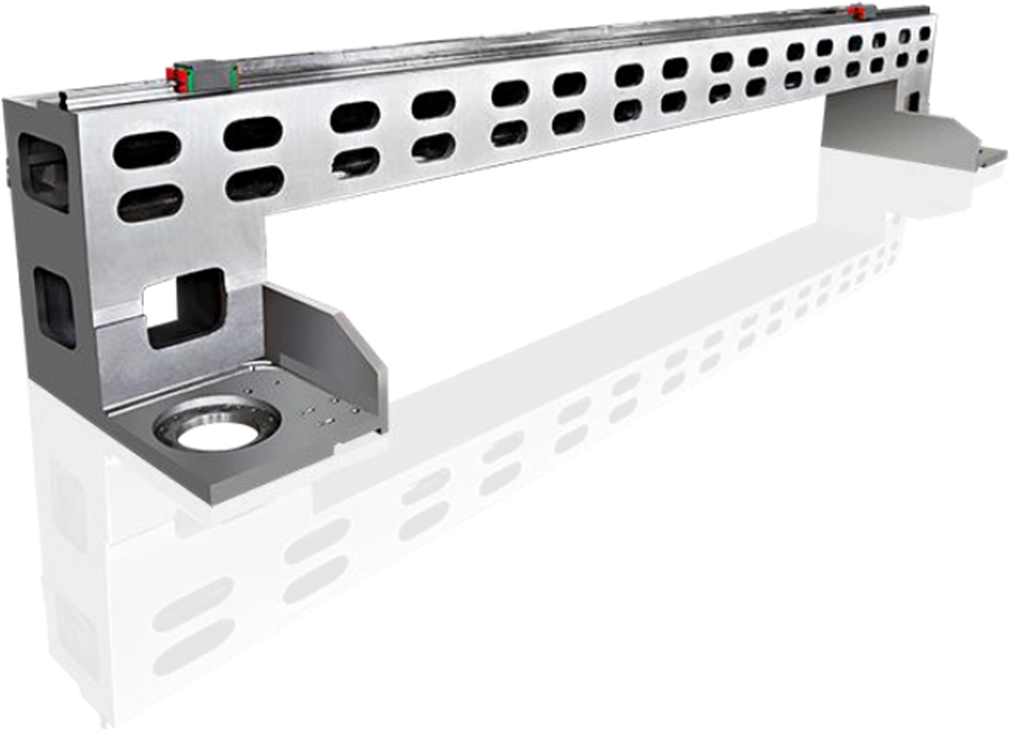

small waterjet cutting machine

The small waterjet cutting machine represents a cutting-edge solution in precision manufacturing, utilizing high-pressure water mixed with abrasive particles to create precise cuts across various materials. This versatile machine operates by focusing a high-pressure water stream, typically ranging from 30,000 to 60,000 PSI, through a small diameter nozzle. The compact design makes it ideal for workshops and small manufacturing facilities while maintaining industrial-grade cutting capabilities. The machine features advanced CNC controls that enable intricate cutting patterns and complex geometries with remarkable accuracy. Its cutting mechanism can handle materials ranging from metals and stone to glass and composites, maintaining clean edges without heat-affected zones. The system includes essential components such as a high-pressure pump, cutting head, abrasive delivery system, and a catch tank, all optimized for space efficiency. Modern small waterjet cutters incorporate smart features like automatic height control, pressure regulation, and user-friendly interface systems that simplify operation while ensuring consistent cutting quality. These machines typically accommodate work pieces up to 4 x 4 feet, making them perfect for small to medium-sized projects while requiring minimal floor space.