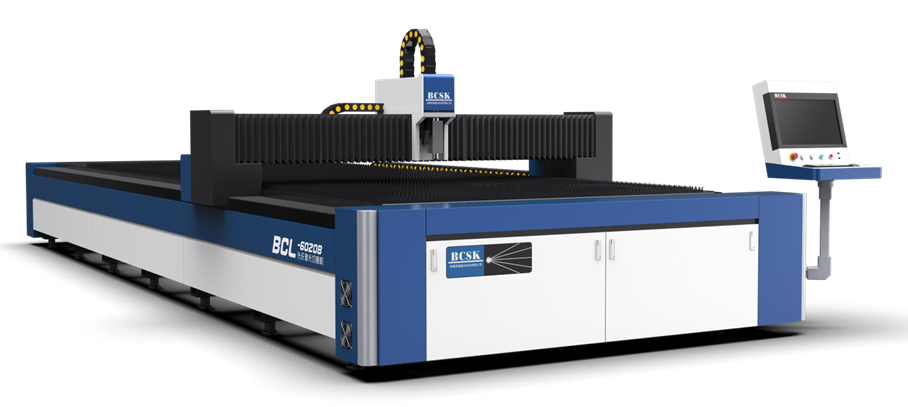

5 axis water jet cutting machine

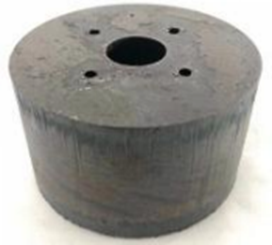

The 5 axis water jet cutting machine represents the pinnacle of precision cutting technology, offering unparalleled versatility in modern manufacturing. This advanced system utilizes high pressure water mixed with abrasive particles to cut through virtually any material with exceptional accuracy. The machine's five axes of motion, including X, Y, Z, A, and B axes, enable complex three dimensional cutting operations that would be impossible with conventional cutting methods. The system can perform intricate beveling, angle cutting, and complex contour following, making it ideal for sophisticated manufacturing requirements. The cutting head can tilt and rotate to create detailed 3D components, while maintaining precise tolerances throughout the cutting process. Operating at pressures up to 60,000 PSI, the water jet system can effectively cut materials ranging from soft rubber to hardened steel, without creating heat affected zones or mechanical stress on the workpiece. The machine's advanced control system ensures precise coordination of all five axes, enabling smooth, continuous motion for optimal cutting quality. This technology has revolutionized manufacturing processes across numerous industries, from aerospace and automotive to architectural and artistic applications.