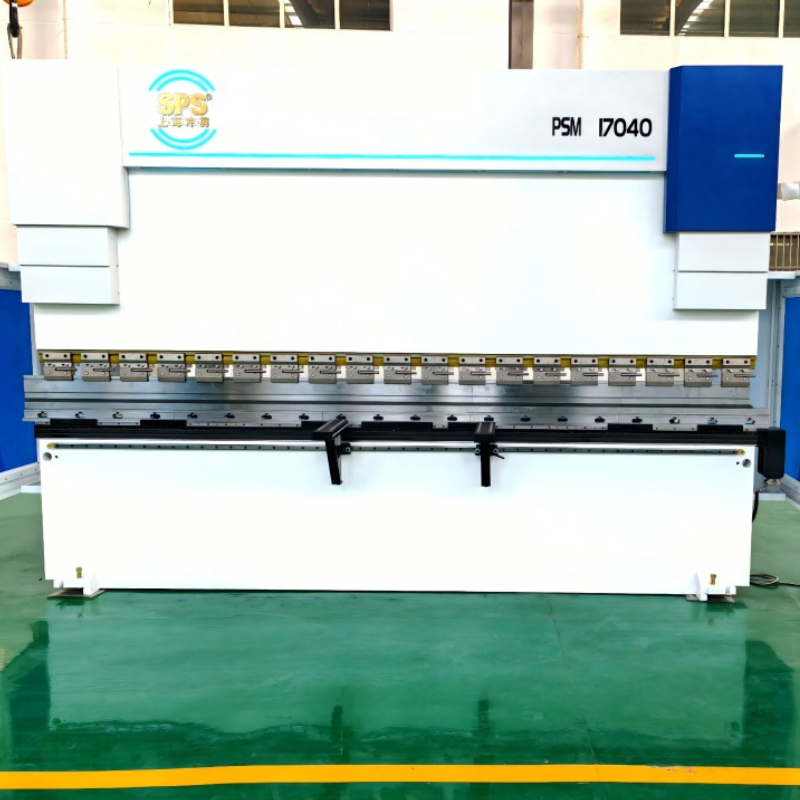

sheet metal brake machine

A sheet metal brake machine is an essential piece of industrial equipment designed for precise metal bending and forming operations. This versatile machine employs advanced hydraulic or mechanical systems to deliver controlled force, enabling accurate bends in sheet metal materials of varying thicknesses. The machine's primary structure consists of a robust beam press, adjustable back gauge, and a series of interchangeable dies that accommodate different bending angles and profiles. Modern sheet metal brakes incorporate computerized numerical control (CNC) systems, allowing for programmable bend sequences and automated operations that ensure consistency across production runs. The machine's working principle involves clamping the metal sheet between the beam and die, followed by precise application of pressure to achieve the desired bend angle. With capabilities ranging from simple 90-degree bends to complex multiple-angle formations, these machines can handle materials including steel, aluminum, copper, and various alloys. The brake's design typically features safety systems such as light curtains and emergency stops, ensuring operator protection during operation. Applications span across numerous industries, from HVAC ductwork and architectural metals to automotive components and custom metalwork projects. The machine's versatility makes it indispensable in both small fabrication shops and large-scale manufacturing facilities, offering the flexibility to produce everything from simple brackets to intricate metal enclosures.