- Gambaran Umum

- Produk Terkait

Aksesori Opsional

| -Pompa grease otomatis | - Lampu Ruang Die |

| - Perangkat Bantalan Die Pneumatik | -Sensor cahaya keselamatan |

| -Tombol Kaki | -Feeder |

| -Perangkat Penggantian Die Cepat | -Uncoiler |

| (Die Lifter, Clamp Dan Die Arm Sepjes) | -Peng lurus |

| - Perangkat Penguncian Geser | - Mekanisme Tangan |

Aksesori standar

| - Inverter | - Perangkat penyesuaian geser listrik (di atas APE-45) | - Indikator kecepatan |

| - Papan sentuh | - Indikator ketinggian cetakan mekanis (APE-45 atau di bawahnya) | - Tempat sambungan sumber udara |

| - Penghitung prasetel | - Indikator ketinggian mati listrik (di atas APE-45) | - Perangkat perlindungan terhadap jatuh kedua |

| - Penghitung prakiraan | - Perangkat keseimbangan | - Perangkat deteksi kesalahan pemberian bahan |

| - Kame listrik | - Indikator sudut kerank | - Soket daya |

| - Pelindung kelebihan beban hidrolik | - Penyangga Pemotong Anti Getaran | - Kotak alat pemeliharaan |

| - Perangkat penyesuaian slaid mekanis (APE-45 atau di bawah) | - Buku panduan operasi |

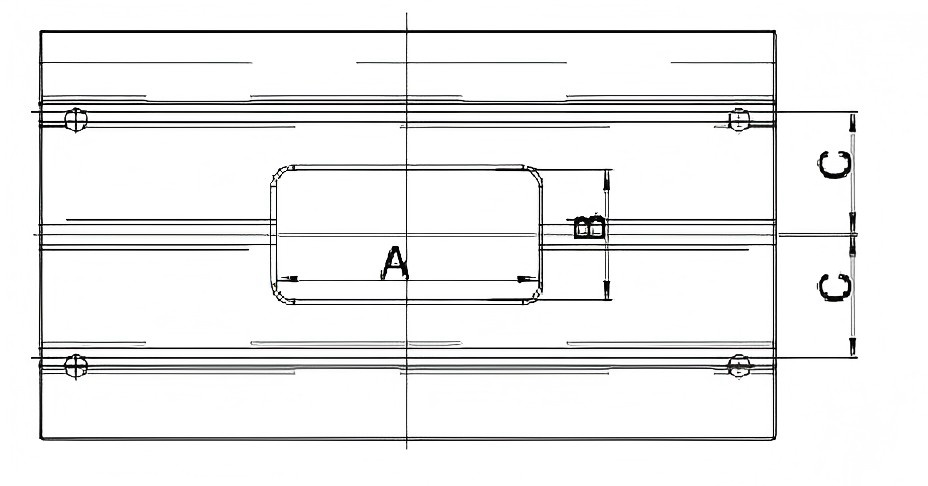

Mac dimensi hine

TIPE |

APE-25 |

APE-45 |

APE-60 |

APE-80 |

APE-110 |

APE-160 |

APE-200 |

APE-250 |

APE-315 |

||||||||

V |

H |

V |

H |

V |

H |

V |

H |

V |

H |

V H |

V |

H |

V |

H |

V |

H |

|

A |

1180 |

1358 |

1454 |

1611 |

1780 |

2000 |

2140 |

2245 |

2245 |

||||||||

B |

750 |

830 |

920 |

1030 |

1160 |

1310 |

1540 |

1700 |

1700 |

||||||||

C |

1993 |

2339 |

2572 |

2675 |

2900 |

3355 |

3635 |

3950 |

3950 |

||||||||

P |

720 |

850 |

900 |

1000 |

1150 |

1260 |

1400 |

1550 |

1650 |

||||||||

E |

320 |

440 |

520 |

600 |

680 |

760 |

820 |

840 |

880 |

||||||||

F |

350 |

460 |

500 |

560 |

650 |

700 |

850 |

920 |

1000 |

||||||||

G |

300 |

350 |

400 |

460 |

520 |

580 |

650 |

700 |

720 |

||||||||

H |

800 |

800 |

800 |

830 |

845 |

915 |

1020 |

1120 |

1120 |

||||||||

Saya |

230255 |

270300 |

300340 |

330375 |

350405 |

450510 |

450500 |

450525 |

500|575 |

||||||||

J |

478 |

520 |

534 |

575 |

645 |

750 |

860 |

970 |

1020 |

||||||||

K |

165 |

230 |

270 |

310 |

350 |

390 |

420 |

430 |

4500 |

||||||||

N |

600 |

666 |

730 |

829 |

945 |

1070 |

1220 |

1360 |

1430 |

||||||||

0 |

1386 |

1564 |

1660 |

1935 |

2104 |

2206 |

2346 |

2569 |

2569 |

||||||||

P |

248 |

249 |

250 |

411 |

411 |

333 |

325 |

325 |

325 |

||||||||

Q |

978 |

1163 |

1167 |

1380 |

1460 |

1578 |

1603 |

1673 |

1673 |

||||||||

R |

648 |

678 |

708 |

718 |

670 |

763 |

838 |

832 |

840 |

||||||||

S |

1180 |

1328 |

1422 |

1595 |

1773 |

2005 |

2137 |

2285 |

2285 |

||||||||

T |

2034 |

2395 |

2618 |

2721 |

2953 |

/ |

3730 |

3970 |

3970 |

||||||||

U |

70 |

80 |

90 |

100 |

110 |

140 |

160 |

180 |

180 |

||||||||

V |

50 |

60 |

70 |

70 |

80 |

90 |

90 |

100 |

100 |

||||||||

Z |

2073 |

2427 |

2646 |

2749 |

3032 |

3456 |

3748 |

4193 |

4193 |

||||||||

TORQUE PENGGERAK TINGGI REM BASAH & KOPLING

| ·Kinerja tinggi | ·Inersia rendah |

| ·Bising rendah | ·Umur pemakaian panjang |

| ·Efisiensi tinggi | ·Tanpa debu |

| ·Torsi tinggi | ·Biaya pemeliharaan rendah |

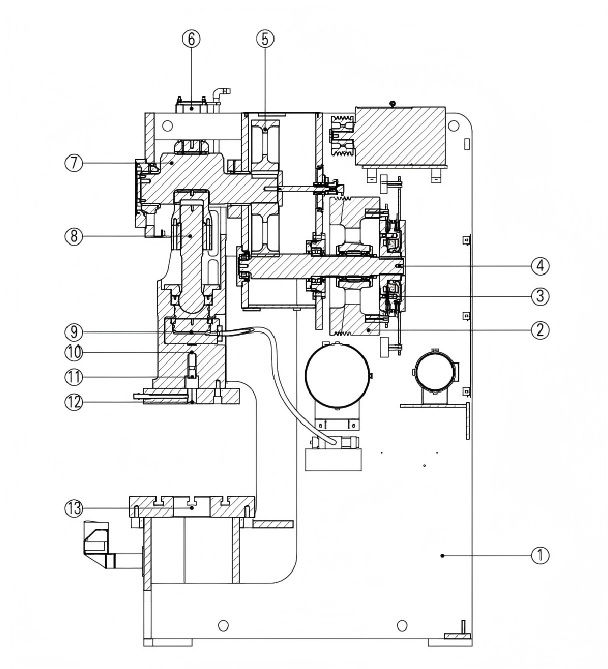

| 1. Rangka Press | 8. Baut Penyesuaian |

| 2. Flywheel | 9. Pelindung Overload Hidrolik (H.O.L. P.) |

| 3. Kopling & Rem | 10. Sliding |

| 4. Poros Inverter Pinion | 11. Pelat Pengusir |

| 5. Gear Utama | 12. Plat Sliding (Dapat Dilepas) |

| 6. Pemantul Keseimbangan | 13. Bolster |

| 7. Poros Engkol |

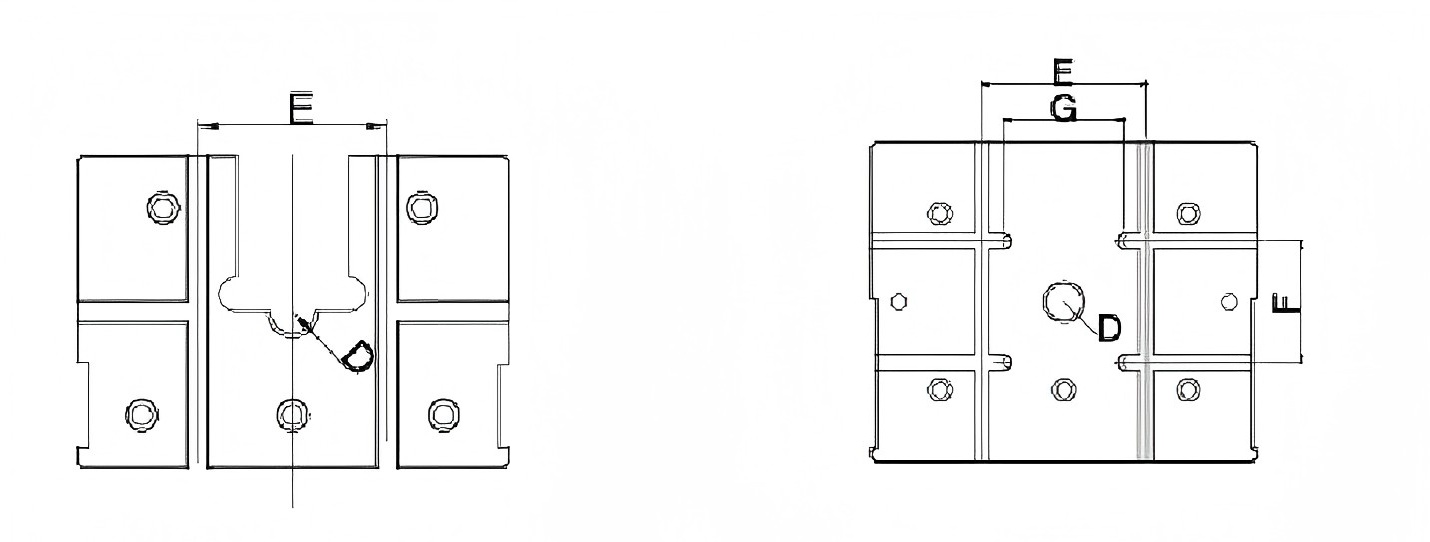

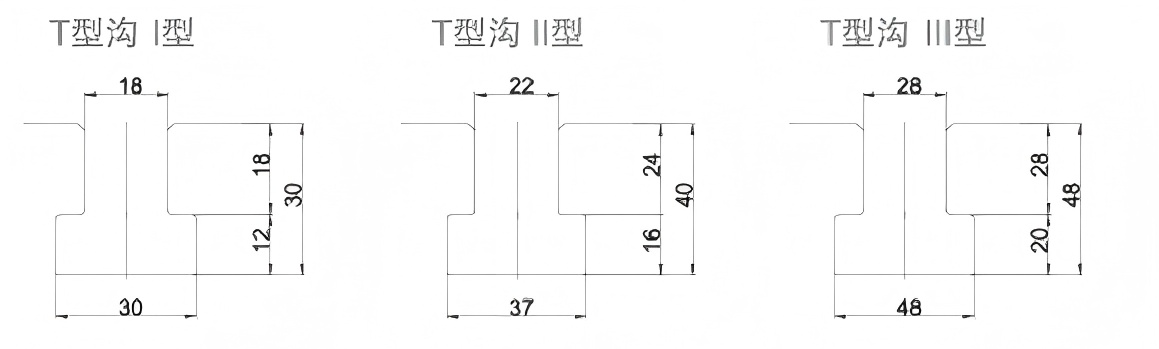

| Area Sliding bekerja ke atas | Area Bolster bekerja ke bawah | ||

|

|

||

APE25-110 |

APE160-315 |

||

Model |

A |

B |

C |

φD |

E |

F |

G |

Garis T |

APE-25 |

200 |

60 |

90 |

38.1 |

250 |

- |

- |

| |

APE-45 |

300 |

100 |

120 |

38.1 |

300 |

- |

- |

Saya |

APE-60 |

300 |

110 |

150 |

50 |

270 |

- |

- |

Ii |

APE-80 |

320 |

120 |

150 |

50 |

300 |

- |

- |

Ii |

APE-110 |

360 |

130 |

160 |

50 |

300 |

- |

- |

iII |

APE-160 |

400 |

150 |

220 |

65 |

300 |

280 |

220 |

iII |

APE-200 |

420 |

180 |

280 |

65 |

300 |

300 |

200 |

iII |

APE-250 |

480 |

200 |

290 |

65 |

300 |

300 |

200 |

iII |

APE-315 |

480 |

200 |

300 |

70 |

300 |

300 |

200 |

iII |

APE-400 |

480 |

200 |

300 |

70 |

300 |

300 |

200 |

iII |

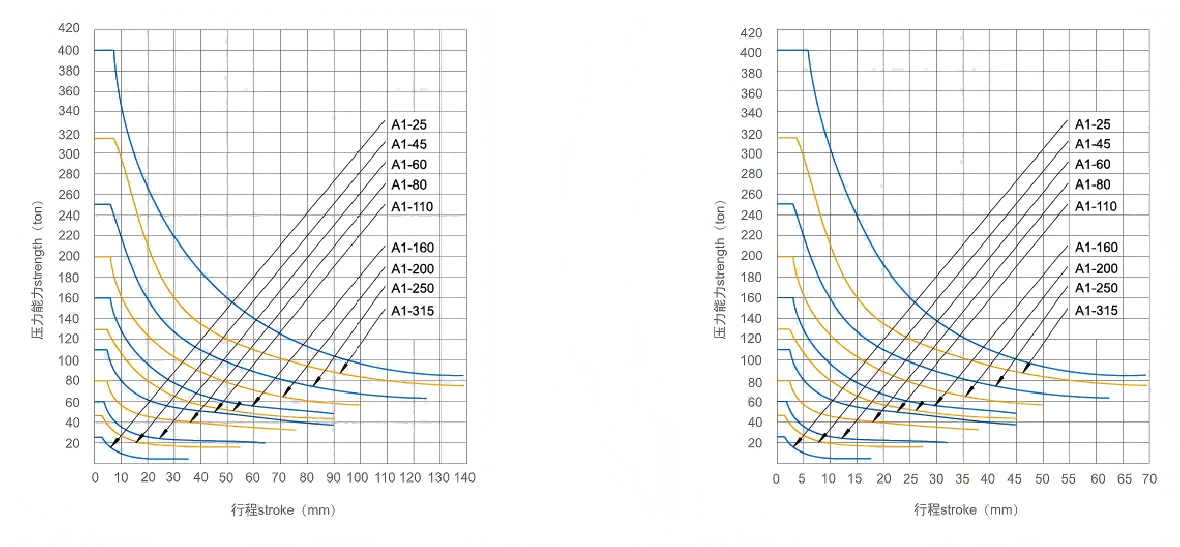

Kurva kapasitas & stroke

Model |

APE-25 |

APE-45 |

APE-60 |

APE-80 |

APE-110 |

|||||||

V |

H |

V |

H |

V |

H |

V |

H |

V |

H |

|||

Kapasitas |

Ton |

25 |

45 |

60 |

80 |

110 |

||||||

Titik Tonase Terukur |

mm |

3.2 |

2.3 |

3.2 |

2.3 |

4 |

2.3 |

5 |

3.2 |

5 |

3.2 |

|

Stroke Slid |

mm |

80 |

30 |

110 |

50 |

130 |

50 |

150 |

60 |

180 |

70 |

|

Stroke/menit |

Variabel |

SPM |

70~110 |

95~190 |

50~95 |

85~175 |

40~85 |

80~160 |

40~75 |

70~140 |

30~60 |

60~120 |

Tetap |

SPM |

75 |

135 |

65 |

125 |

60 |

120 |

60 |

100 |

50 |

90 |

|

Tinggi Mati Maksimal |

mm |

230 |

255 |

270 |

300 |

300 |

340 |

330 |

375 |

350 |

405 |

|

Penyesuaian Tinggi Mati |

mm |

50 |

60 |

70 |

80 |

90 |

||||||

Kedalaman Kerongkongan |

mm |

170 |

230 |

270 |

310 |

350 |

||||||

Area geser |

mm |

350x300x50 |

430x350x60 |

500×400×70 |

560×460×70 |

650x520x80 |

||||||

Area bolster |

mm |

720x320x70 |

850x440x80 |

900×520×90 |

1000×600×100 |

1150×680×110 |

||||||

Lubang shank |

mm |

φ38.1 |

φ38.1 |

φ50 |

φ50 |

050 |

||||||

Motor utama |

KWXP |

4x4 |

5.5x4 |

5.5x4 |

7,5x4 |

11×4 |

||||||

Perangkat penyesuaian geser |

- |

operasi manual |

operasi manual |

penggerak Listrik |

listrik penggerak |

listrik |

||||||

Tekanan udara |

Kg/cm2 |

6 |

6 |

6 |

6 |

6 |

||||||

Tinggi kerja |

mm |

800 |

800 |

800 |

830 |

845 |

||||||

Kapasitas Penyangga Mati |

Ton |

- |

2.6 |

3.6 |

6.3 |

8 |

||||||

Strok Penyangga Mati |

mm |

- |

60 |

70 |

70 |

80 |

||||||

Area efektif bantalan cetakan |

mm |

- |

300×250 |

350×300 |

450×310 |

500x350 |

||||||

Dimensi keseluruhan |

mm |

832×1060×2165 |

860×1350×2375 |

970×1390×2585 |

1180×1755×2685 |

1305×1935×2915 |

||||||

Model |

APE-160 |

APE-200 |

APE-250 |

APE-315 |

||||||

V |

H |

V |

H |

V |

H |

V |

H |

|||

Kapasitas |

Ton |

160 |

200 |

250 |

315 |

|||||

Titik Tonase Terukur |

mm |

6 |

4 |

6 |

4 |

6 |

4 |

8 |

6 |

|

Stroke Slid |

mm |

200 |

80 |

200 |

100 |

250 |

100 |

250 |

100 |

|

Stroke/menit |

Variabel |

SPM |

25~55 |

50~100 |

20~50 |

45~80 |

20~45 |

40~70 |

20~40 |

30~50 |

Tetap |

SPM |

45 |

80 |

35 |

60 |

30 |

55 |

30 |

40 |

|

Tinggi Mati Maksimal |

mm |

450 |

510 |

450 |

500 |

450 |

525 |

500 |

575 |

|

Penyesuaian Tinggi Mati |

mm |

100 |

110 |

120 |

120 |

|||||

Kedalaman Kerongkongan |

mm |

350 |

420 |

430 |

450 |

|||||

Area geser |

mm |

700x580x90 |

850x650x90 |

920x700x100 |

1000x720x100 |

|||||

Area bolster |

mm |

1260×760×140 |

1400×820x160 |

1550×840×180 |

1650×880×180 |

|||||

Lubang shank |

mm |

φ65 |

φ65 |

φ65 |

φ70 |

|||||

Motor utama |

KWXP |

15×4 |

18.5×4 |

22x4 |

30x4 |

|||||

Perangkat penyesuaian geser |

- |

listrik |

listrik |

listrik |

listrik |

|||||

Tekanan udara |

Kg/cm2 |

6 |

6 |

6 |

6 |

|||||

Tinggi kerja |

mm |

915 |

1020 |

1120 |

1120 |

|||||

Kapasitas Penyangga Mati |

Ton |

10 |

10 |

14 |

16 |

|||||

Strok Penyangga Mati |

mm |

80 |

100 |

100 |

110 |

|||||

Area efektif bantalan cetakan |

mm |

660x420 |

660×460 |

600x460 |

700x460 |

|||||

Dimensi keseluruhan |

mm |

1425×2060×3300 |

1575×2300×3675 |

1740×2345×4000 |

1900x2850×4200 |

|||||