- Overview

- Related Products

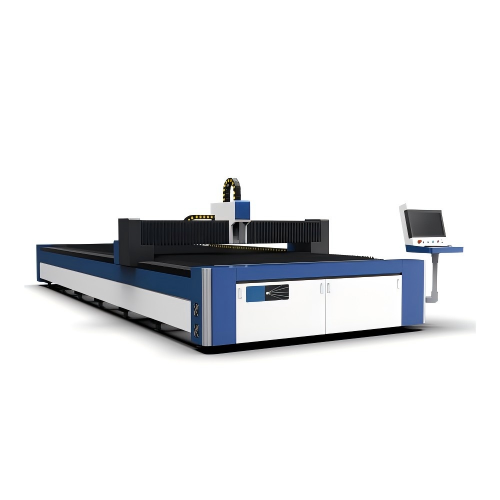

PERFORMANCE

1-1. High performance qualified fiber generator,which is high reliability and longevity of service.

1-2. Higher cutting speed and efficient,Max cutting speed can be reach 10m/min in cutting 1mm mild steel.

1-3. Free maintenance for fiber laser generator.Max life reach to more than 100000 hours.

1-4. Smooth cutting surface,little deformation,pretty leveling appearance.

1-5. Import transmission parts and servo motor, high dynamic movement performance, high cutting precision.

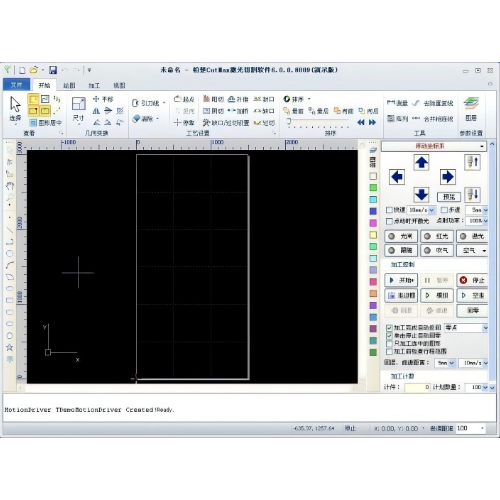

1-6. Dedicated software enables graphic or text into instantly designed pr processed.

TECHNICAL DATA

NO |

Name |

Parameter |

1 |

Laser type |

Fiber laser |

2 |

The maximum cutting thickness for MS |

20mm |

3 |

The maximum cutting thickness for SS |

10mm |

4 |

Rated output power |

3000W |

5 |

Laser wave length |

1080±5nm |

6 |

X/Y/Z axis stoke |

1510 /3010 / 120mm |

7 |

X/Y axis positioning accuracy |

≤0.05mm/m |

8 |

X/Y axis repositioning accuracy |

≤0.05mm |

9 |

Max positioning speed |

74m/min |

10 |

Cutting table size |

3000x1500mm |

11 |

Power supply requirement |

Customized |

12 |

Measurement |

4410x2200x1700mm |

13 |

Weight |

2500kg |

STANDARD COMPONENTS

Name |

Brand |

Laser Source |

MAX, China |

Laser head |

RayTools,Swiss |

Machine structure |

SPS,China |

X 、Y Axis gear |

ROR,Germany |

Linear guide |

Hiwin,Taiwan |

Electrics |

Schneider,France |

Proportional valve |

SMC,Japan |

X axis Servo motor and driver |

Fuji ,Japan |

Y axis servo motor and driver |

Fuji ,Japan |

Reducer |

Motovario, France |

Air control |

SMC,Japan |

Software |

CYPCUT,Shanghai |

STANDARD CONFIGURATION

|

The main frame adopts the gantry structure welded by all steel plates to ensure the long-term stability of the model without deformation ★The bed is formed once by imported gantry milling ★Using gantry rack double guide rail, double servo drive structure |

|

★Improve the stability and rigidity of the Y-axis beam |

|

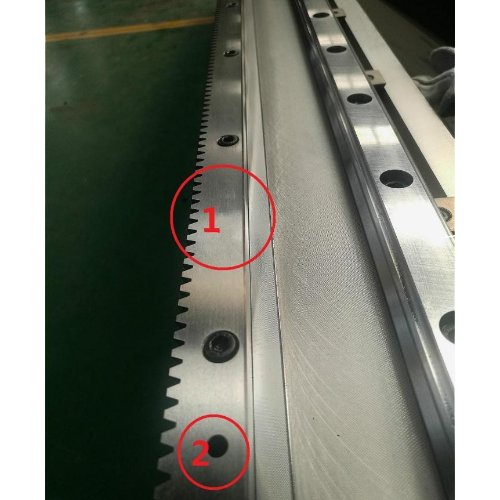

1- Germany ROR rack, ground on all sides, improves precision |

|

1-Taiwan "HIWIN" rail 2-The oblique pressure block design prevents the guide rail from displacement |

|

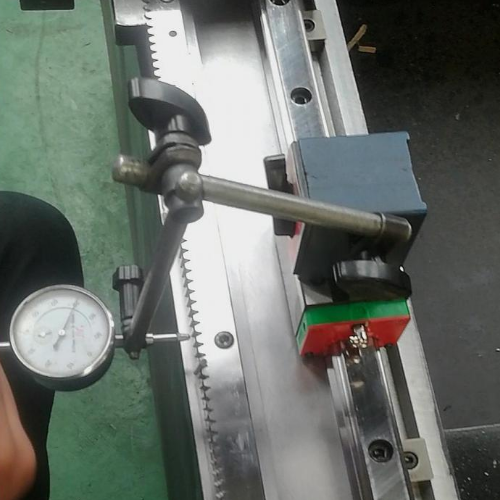

The guide rail and rack are calibrated by a precision collimator with an accuracy of ±0.02mm |

|

Servo motor It adopts Japanese Fuji servo motor drive and imported transmission system to ensure the operation accuracy and reliability of the equipment. |

|

Fiber Laser Source Max, China |

|

Laser Head It adopts Raytools,Swiss Non-contact sensing device |

|

Control System CYPCUT,Shanghai |

|

Reducer Motovario, France |

|

Water Chiller Hanli, China |

|

Proportional valve SMC, Japan |

|

Electrics Schneider,France |

CUTTING PARAMETER

| 3000W Cutting parameter | |||

| Material | Thickness(mm) | Speed(m/min) | Gas |

| Stainless steel | 1 | 35-45 | N2 |

| 2 | 22-24 | N2 | |

| 3 | 9-10 | N2 | |

| 4 | 6.6 | N2 | |

| 6 | 2.7 | N2 | |

| 8 | 1.2 | N2 | |

| Carbon steel | 1 | 30-35 | Air |

| 3 | 3.6-4 | O2 | |

| 6 | 2.7 | O2 | |

| 8 | 2.2 | O2 | |

| 10 | 1.5 | O2 | |

| 12 | 1.0 | O2 | |

| 16 | 0.5-0.75 | O2 | |

| Aluminum | 1 | 35-45 | N2 |

| 2 | 22-24 | N2 | |

| 4 | 6.0 | N2 | |

| 6 | 2.0 | N2 | |

| Brass | 2 | 13-15 | N2 |

| 3 | 5-6 | N2 | |

| 5 | 2.2 | N2 | |

|

Note: Different materials, gas pressures, etc. may cause speed differences. Cutting gas purity requirements: 99.95%~99.995%, the higher the purity, the better the cutting surface effect. | |||

AFTER-SALES SERVICE

1. Our machine is easy to use. Operation manual and teaching video will be sent out with machine.

2. We guarantee machine quality for 12 months, during this period, if spare parts of the machine are not man-made damage, we can send the component to the customer by DHL, TNT freely.

3. Our factory provide the service for the customer forever, if the customer need our operation help,can contact us by Skype, Email and Telephone at any time, we provide 24 hours on-line service.