hydraulic press brake attachment

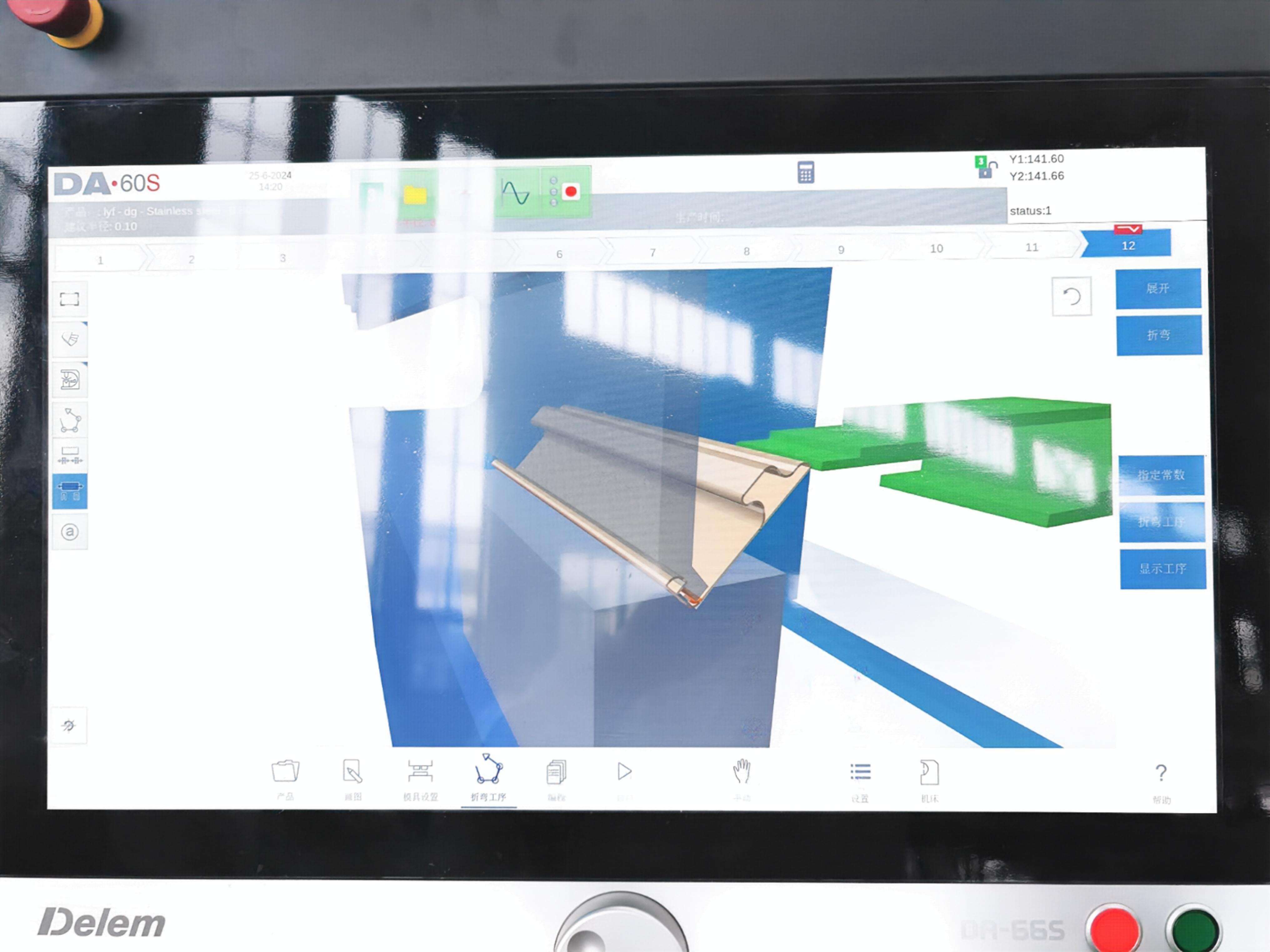

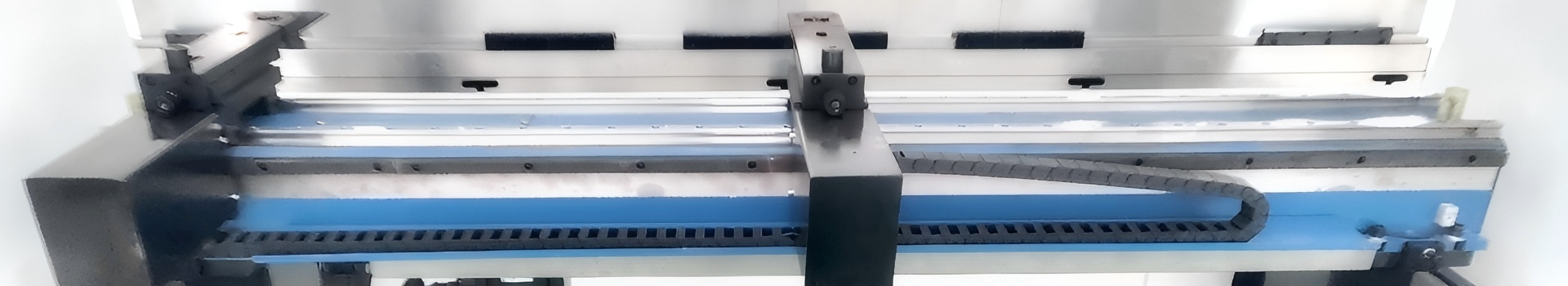

The hydraulic press brake attachment represents a sophisticated advancement in metal forming technology, engineered to deliver precise bending and forming operations across various metal materials. This versatile tool integrates seamlessly with existing press brake systems, enhancing their capabilities through advanced hydraulic power transmission. The attachment features a robust hydraulic system that generates consistent pressure distribution, enabling uniform bending results across the entire workpiece length. Its precision-engineered components include adjustable pressure controls, quick-change die holders, and advanced safety mechanisms. The system's intelligent pressure monitoring ensures optimal force application, while its modular design facilitates easy maintenance and customization. Applications span across multiple industries, from automotive manufacturing to architectural metalwork, enabling the creation of complex bend profiles with exceptional accuracy. The attachment's sophisticated control interface allows operators to program and store multiple bend sequences, significantly reducing setup time and enhancing productivity. Modern safety features include pressure relief valves, emergency stop functions, and protective guarding systems, ensuring operator safety without compromising performance. This technological advancement has revolutionized metal forming processes, making it an indispensable tool for both small-scale workshops and large manufacturing facilities.