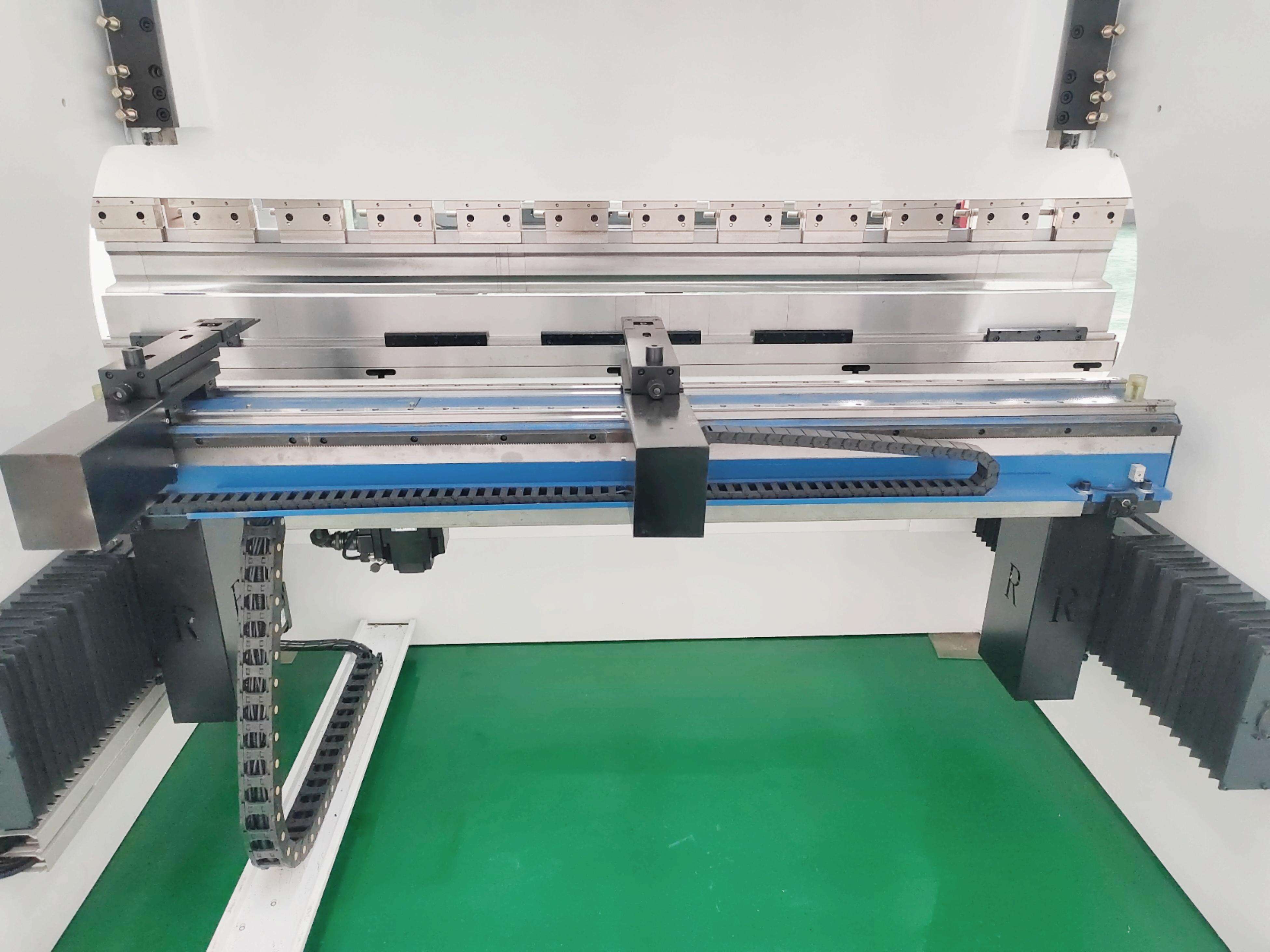

hydraulic press brake machine

The hydraulic press brake machine represents a cornerstone in modern metal fabrication, combining powerful hydraulic systems with precise control mechanisms to deliver exceptional bending and forming capabilities. This sophisticated equipment operates by applying controlled force through a hydraulic system to bend sheet metal and plate materials into predetermined angles and shapes. The machine consists of a robust frame, hydraulic cylinders, upper and lower tooling, and an advanced control system that ensures accuracy and repeatability. Modern hydraulic press brakes feature CNC controls, allowing for programmable bend sequences and automated operations that significantly enhance productivity. The machine's versatility enables it to handle various material thicknesses and types, from thin sheet metal to heavy plate steel, making it indispensable in manufacturing operations. With adjustable stroke lengths, variable pressure control, and multiple axis backgauge systems, operators can achieve complex bends with exceptional precision. These machines typically offer working lengths from 4 to 20 feet and tonnage capacities ranging from 25 to 1000 tons, accommodating diverse industrial requirements. Safety features include light curtains, emergency stop systems, and operator protection guards, ensuring secure operation while maintaining high productivity levels.