laser cutting machine business

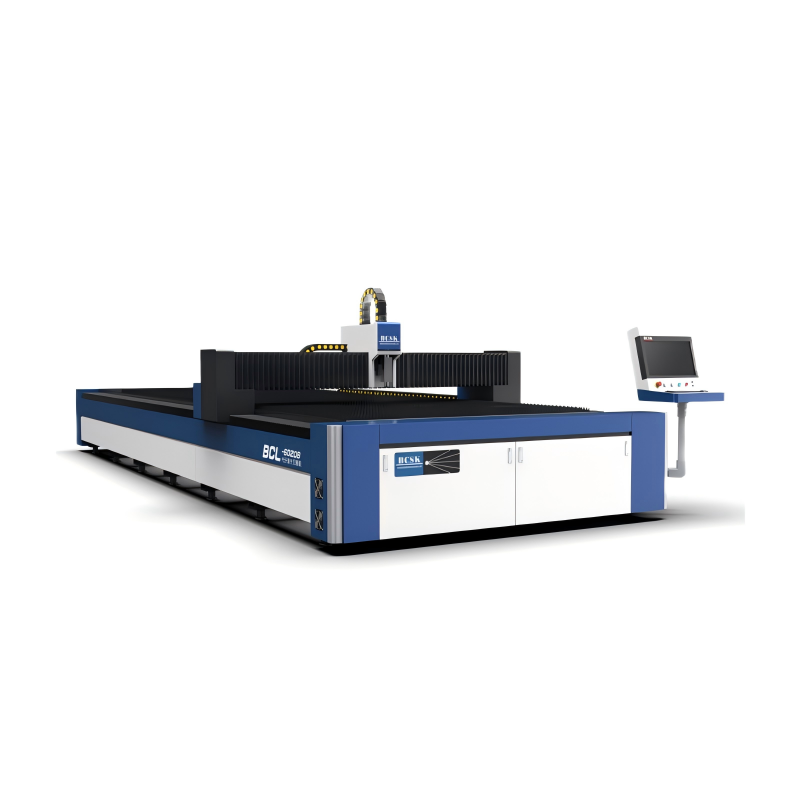

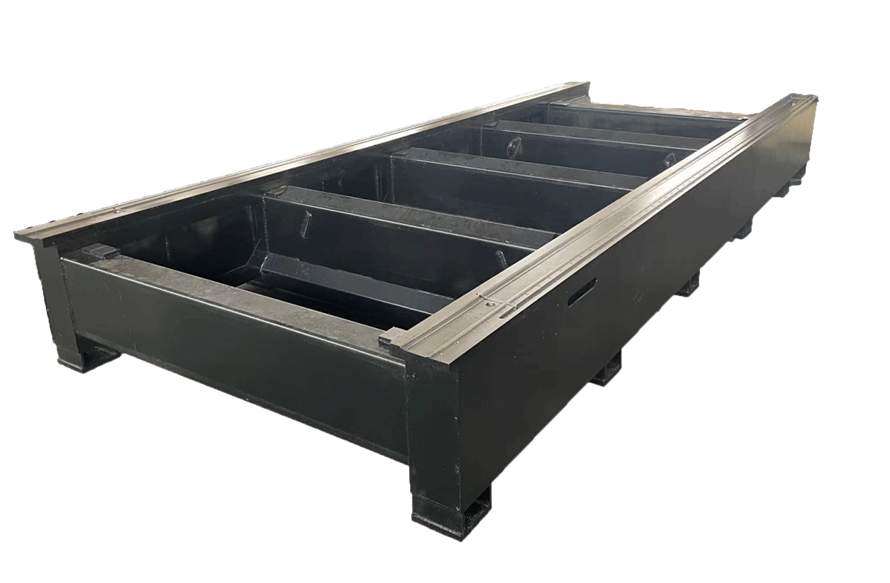

Laser cutting machines represent a cornerstone of modern manufacturing technology, offering precision, versatility, and efficiency in material processing. These sophisticated systems utilize focused laser beams to cut through various materials with exceptional accuracy, revolutionizing production processes across multiple industries. The technology employs high-powered lasers that can be precisely controlled through advanced computer numerical control (CNC) systems, enabling complex cutting patterns and intricate designs. Modern laser cutting machines feature state-of-the-art fiber laser sources, providing superior beam quality and enhanced cutting capabilities. These machines can process a wide range of materials, including metals, plastics, wood, and composites, with cutting thicknesses varying from thin sheets to substantial plates. The technology incorporates advanced features such as automatic nozzle changing, real-time process monitoring, and intelligent material handling systems, streamlining production workflows and minimizing operator intervention. Applications span diverse sectors, including automotive manufacturing, aerospace components, architectural elements, and consumer products, making laser cutting machines indispensable in today's manufacturing landscape.